|

Abakan Q1 Newsletter

Setting New Benchmarks with Metals and Advanced Materials

|

|

To our Valued Shareholders,

Our major goals for 2014 are two-fold: 1) Scaling-up PComP powder production to meet the growing demand, which would facilitate accelerated adoption of our PComP products while increasing operating revenues; and 2) Completing the development and qualification of our CermaClad corrosion-resistant clad pipe product and establishing our 4-line clad pipe manufacturing plant in Indonesia, which would allow us to commence production in 2015. I am glad to report that we are on track to meet both of our major goals.

We recently secured a $1.5 million loan from the State of Ohio to scale-up PComP powder production from 3 tons/year to 180 tons/year, which translates to approximately $23 million in annual revenues. This loan will also assist us with setting-up a 2-cell thermal spray coating shop to enter the high margin coating services market, which would translate to approximately $6 million in annual revenues.

As far as our CermaClad corrosion-resistant clad pipe product is concerned, we have made significant progress over the past 3 months and expect to have clad pipe sections ready to be sent for testing and qualification to Oil and Gas majors soon. The testing and qualification of clad pipe sections would enable us to not only gain very high credibility with the Oil and Gas majors, but also may lead to one or more of those Oil and Gas majors or Offshore Pipe Manufacturers to entertain the thought of buying out the entire production capacity of our Indonesian clad pipe plant, given the significant shortage in availability of corrosion-resistant clad pipes.

Furthermore, we recently received a $2.75 million funding from Canadian agencies to set-up a development and qualification facility for our CermaClad wear-resistant clad pipe product. This wear-resistant clad pipe product is expected to significantly minimize the $4 billion per year in downtime, maintenance and replacement costs associated with pipelines used for transporting the highly abrasive oil sands. Based on the milestones, traction, and progress made in the first quarter of 2013, we are confident that we are on track for a phenomenal 2014. We appreciate your continued support.

Sincerely,

Robert Miller |

|

Secured a $1.5 Million Loan from State of Ohio to Scale-Up PComP Powder Production and Expand Coating Services

Abakan’s subsidiary, MesoCoat, Inc., was awarded a $1.5 million loan from the Ohio Department of Development’s Ohio Third Frontier Commission to scale up PComP™ production and expand PComP™ coating services.

Mr. Robert Miller, Abakan, Inc.’s CEO stated “Our PComP™ current powder production expansion plan is ramping up annual production to 18 tons increasing sales to $240,000 per month. The $1.5 million loan will assist MesoCoat to increase the scale up of PComP™ production from 18 tons to 160 tons per year increasing projected powder sales revenues to $1,600,000 per month and thermal spray revenues of $1,000,000 per month, over the next few years. We anticipate that the PComP™ production ramp up will result in an average annual growth rate of approximately 75% over three years from our fiscal year end May 2015 to May 2018.” Mr. Robert Miller, Abakan, Inc.’s CEO stated “Our PComP™ current powder production expansion plan is ramping up annual production to 18 tons increasing sales to $240,000 per month. The $1.5 million loan will assist MesoCoat to increase the scale up of PComP™ production from 18 tons to 160 tons per year increasing projected powder sales revenues to $1,600,000 per month and thermal spray revenues of $1,000,000 per month, over the next few years. We anticipate that the PComP™ production ramp up will result in an average annual growth rate of approximately 75% over three years from our fiscal year end May 2015 to May 2018.”

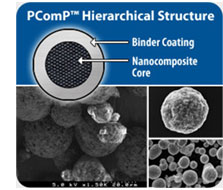

Mr. Miller further stated, “PComP™ nanocomposite powder coatings have shown impressive results in the three major aspects of performance, time, and value proposition of cost versus life. Our PComP™ powders have consistently demonstrated 3 to 8 times longer life for treated components, at lower life-cycle costs, which lead to reductions in downtime and losses. We believe that this is the right time to step-up our efforts towards driving rapid adoption of these breakthrough coatings.”

Read More »

|

|

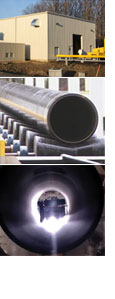

CermaClad Wins the Top Corrosion Innovation Award

Abakan’s subsidiary, MesoCoat, Inc. (“MesoCoat”) received the highly prestigious National Association of Corrosion Engineers (NACE) Materials Performance (MP) Corrosion Innovation of the Year Award in the Coatings and Linings category. The award was conferred upon MesoCoat’s CermaClad™ high-speed, large-area, metal cladding technology that extends the useful life of metal assets while significantly reducing associated maintenance and downtime costs. CermaClad™ technology utilizes a high-intensity arc lamp to rapidly fuse protective, proprietary cladding materials onto the internal surface of steel pipe and tube. Abakan’s subsidiary, MesoCoat, Inc. (“MesoCoat”) received the highly prestigious National Association of Corrosion Engineers (NACE) Materials Performance (MP) Corrosion Innovation of the Year Award in the Coatings and Linings category. The award was conferred upon MesoCoat’s CermaClad™ high-speed, large-area, metal cladding technology that extends the useful life of metal assets while significantly reducing associated maintenance and downtime costs. CermaClad™ technology utilizes a high-intensity arc lamp to rapidly fuse protective, proprietary cladding materials onto the internal surface of steel pipe and tube.

NACE International serves approximately 30,000 members in 116 countries. It is recognized globally as the premier authority for corrosion control solutions and has become the leader in developing corrosion prevention and control standards, certification and education. Honoring the most important innovations impacting corrosion control today, the Corrosion Innovation of the Year awards showcase progressive technological developments in all aspects of corrosion prevention and mitigation and recognize the innovators who have created revolutionary solutions to combat corrosion and protect vital assets from its damaging effects. A panel of leading corrosion experts rated the corrosion-control innovations and the top 10 innovations were announced March 10th at CORROSION 2014 - NACE International’s annual corrosion conference and exposition. CermaClad™ received the highest ranking.

Read More »

|

|

MesoCoat Receives EPA Award to Develop Galvanizing Replacement

MesoCoat received a Phase One SBIR Grant from the Environmental Protection Agency (EPA) for a six month project to develop CermaClad™, Abakan's environmentally friendly high-speed large-area metal cladding technology, as a replacement alternative for the highly toxic galvanizing process currently in use. The EPA funding will be used to develop Abakan’s CermaClad™ (Low Thickness) product for infrastructure applications.

Frost and Sullivan expects the global demand for zinc to be 13.2 million metric tons (MT) in 2014, of which 50% of the total production is to be used for galvanizing steel against corrosion, which translates into an approximately $18 billion market for galvanizing globally. However, current galvanizing methods rely on toxic processes that utilize hazardous and noxious materials which generate toxic emissions. Chemical baths used during the galvanizing (pickling) process are among the leading producers of industrial waste which is ultimately disposed in landfills, injected into underground wells or recycled.

MesoCoat will use its high-speed, large-area CermaClad™ metal cladding technology to apply very thin layers of proprietary zinc materials to prevent corrosion by forming a physical barrier that acts as a sacrificial anode when the barrier is in danger. The primary application of CermaClad™ LT zinc cladding is intended for corrosion protection for steel components including bridge decks, structures and beams, marine, power generation, refineries, grid transmission towers, railroads, oil and gas infrastructure.

Read More »

|

|

Corrosion Continues to Threaten Production from Large Oil Reserves

A Reuters article on Kashagan, “the world’s biggest oil find in 35 years” is a testament to the growing and critical need for pipelines that can withstand the extreme assault of corrosion as we continue to encounter oilfields with extremely high content of corrosive elements; the International Energy Agency estimates that 7 out of 10 remaining oilfield reserves in the world are highly corrosive.

Among the technological challenges that are being faced to put several oilfields into production; one of the most important challenge is the material selection for the extreme corrosive environments encountered in almost 70% of the remaining oilfields. High pressures and temperatures coupled with high content of corrosive CO2 and H2S, leads to the high demand and need for pipes and oilfield components that can withstand the assault of corrosion. Clad pipes have proven to be the most economically viable option for production and transportation of sour oil and gas.

As we continue to make significant progress with the development and qualification of our corrosion-resistant clad pipe product; we continue to see tremendous growth for corrosion-resistant clad pipes, without which several large projects like Kashagan might come to a grinding halt.

Read More »

|

|

Abakan Files Quarterly Report with the SEC

As used herein, the terms “Abakan”, “we,” “our,” and “us” refer to Abakan Inc., a Nevada corporation, and its consolidated subsidiaries, unless otherwise indicated. In the opinion of management, the accompanying financial statements included in this Form 10-Q reflect all adjustments (consisting only of normal recurring accruals) necessary for a fair presentation of the results of operations for the periods presented. The results of operations for the periods presented are not necessarily indicative of the results to be expected for the full year.

Read More »

|

|

|