Holdings

CermaClad™ - Clad Products

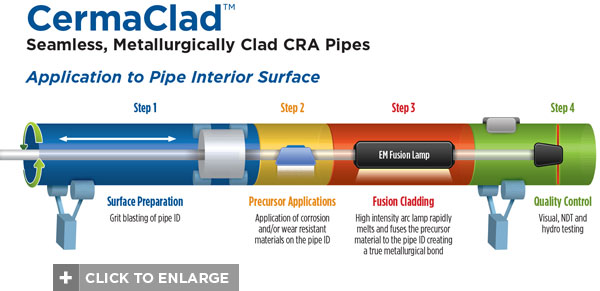

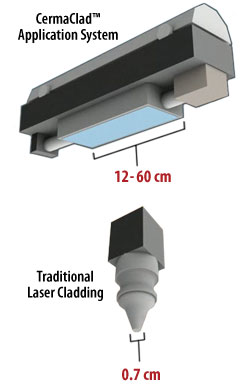

CermaClad™ technology utilizes a high-intensity light source to rapidly fuse protective cladding material on steel pipes and tubes (both internal and external surfaces), plates, sheets, and bars. CermaClad™ offers high-speed fusion cladding that is faster, better, and cost-competitive with other processes used to clad metal surfaces with corrosion resistant alloy (CRA), wear resistant alloy, cermet, ceramic, and metal powders.

CermaClad™ high speed fusion cladding process has the potential of redefining the $3.8 billion metal cladding industry; as the process is 15-100X faster than the conventional weld and laser cladding processes, offers better metallurgical properties, and is cost competitive. The speed of this process would ensure that metal cladding can match the line speed of steel mills, and reduce lead times for clad pipes and tubes by 75-80%. Experts estimate that a less expensive, and faster cladding process will increase the global metal cladding market by 100% in the next three years to $7.6 billion; this increase will be driven by significant investments being made by oil and gas companies in deep water projects. Abakan is currently focusing on deepwater Oil and Gas, Oil Sands, and Slurry line applications where the regular corrosion protection for tubular goods is insufficient, and requires Carbon Steel pipes cladded with Corrosion and Wear Resistant Alloys.

Metal Cladding with expensive corrosion and wear resistant material is considered to be the best option for corrosion and wear protection, but the slowness of the process that causes huge lead times, cladding costs that are 4-5X the cost of carbon steel, and undesirable properties (pinholes, roughness) of the final cladding have limited its application in the industry. We has spoken to a number of companies in the Oil and Gas, Infrastructures, Mining, Defense and Marine industries, and have received a common response from most of them: "If you can reduce the lead time to months instead of years, reduce the cost by about 25-30%, and provide smooth and pinhole-free cladding, we would prefer using clad metal over other options." The CermaClad™ process addresses all these shortcomings associated with the current metal cladding processes; and hence offers a process that meets the industry demands to the ' T '.

CermaClad™ - Value Proposition

Time

Time

- 15-100X faster than weld/laser cladding

- Coverage of 75-580 sq.ft./hour with a single system

- Matches line speed of steel mills , and thus avoiding any delay in the project schedule and scope

Performance

- True metallurgical bond, >75,000 psi

- Minimal heat input to the substrate leading to strength retention of substrate

- Field portable system under development

Cost

- Reduced lead time leading to massive savings in the overall project costs

- Allows application of thinner clad layer leading huge saving in material costs

- Faster process leads to lower operating costs

CermaClad™ Product Line

CermaClad CRA (Corrosion Resistant)

CermaClad CR cost-effective clad products are made from Corrosion Resistant Alloys (Alloy 626, 825, 904L, Monel 400) and Stainless Steel at cladding thickness between 2.5mm – 4mm; using our proprietary CermaClad™ high speed fusion cladding technology that provides ultimate corrosion resistance, true metallurgical bond, with no damage to the substrate and better metallurgical properties than competitive cladding processes.

Applications:

- Oil and Gas (OCTG ID, Tankers, Vessels, Reactors)

- Oil Sands (Slurry Lines ID)

- Mining (Wear plates)

- Power Generation (Boiler tubes)

CermaClad WR (Wear Resistant)

CermaClad WR cost-effective clad products are made from Wear Resistant materials like Chromium Carbide and Tungsten Carbide at cladding thickness between 5mm – 8mm; using our proprietary CermaClad™ high speed fusion cladding technology that provides ultimate wear resistance, true metallurgical bond, with no damage to the substrate and better metallurgical properties than competitive cladding processes.

Applications:

- Oil Sands (Slurry Lines ID)

- Oil and Gas (OCTG ID, Tankers, Vessels, Reactors)

- Mining (Wear plates)

- Power Generation (Boiler tubes)

CermaClad LT (Low Thickness)

CermaClad LT cost-effective clad products are made from corrosion resistant materials like Stainless Steel and Aluminum at cladding thickness between 0.1mm – 1mm; using our proprietary CermaClad™ high speed fusion cladding technology that provides ultimate corrosion resistance, true metallurgical bond, with no damage to the substrate and better metallurgical properties than competitive paint systems and cladding processes.

Applications:

- Shipbuilding (Ballast and Cargo Tanks)

- Infrastructure (Rebars)

- Bridges (Steel Structures)

- Oil and Gas (Pipeline OD)